Green products are becoming increasingly important to homeowners and purchasers in and beyond Boston. People are becoming more and more aware of how bad some building materials, like drywall, can be for the environment.

In reality, 52% of all CO2 emissions come from buildings. This includes the energy they use and the emissions that are made when building materials are made.

The need for eco-friendly materials is on the rise in the building industry as a whole, and drywall materials are no exception. This places drywall firms in an unusual position.

On the one hand, it is natural to wish to meet any consumer requirement. On the other side, this may require the purchase of new equipment, resources, and even training for your crew.

Drywall is the most common type of interior wallboard, and its production consumes a great deal of energy, which results in a great deal of CO2 emissions. Consequently, several homeowners are searching for environmentally friendly drywall choices.

Let’s look at some of the options so you know what to suggest when homeowners, buyers, or developers ask for “green wallboard.”

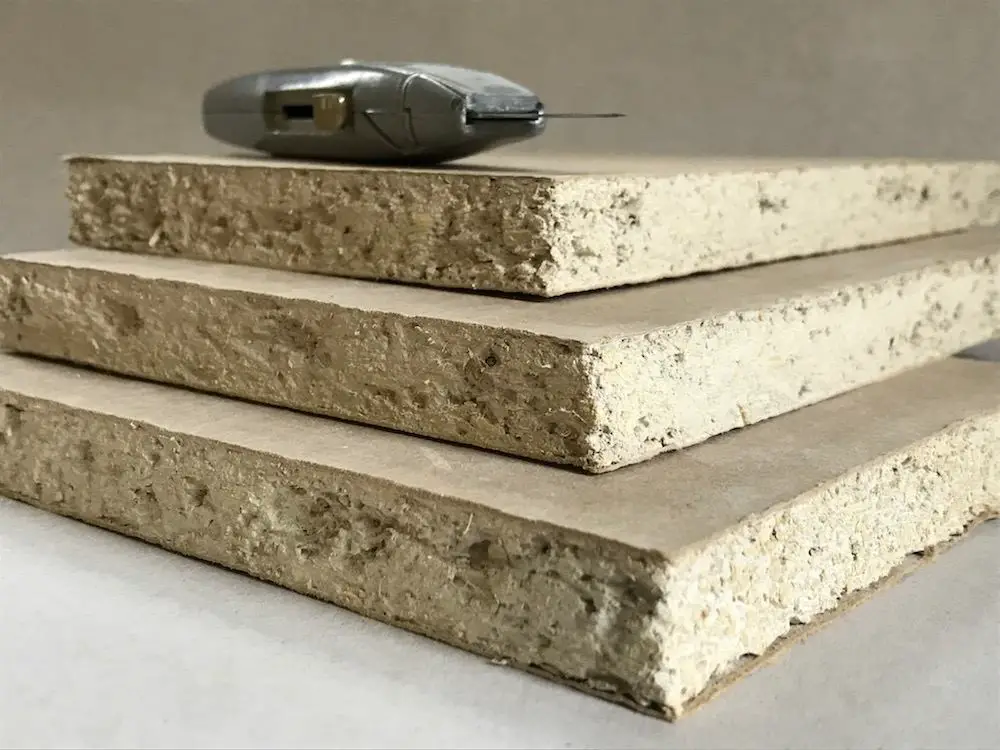

Hempcrete

Hempcrete is composed of hemp shivs (tiny bits of the plant’s stalk), a lime-based binder, and water. This mixture is then poured into molds, or “formwork,” attached to a wooden frame to replace conventional insulating materials.

Compared to typical construction materials, industrial hemp processing requires extremely little embodied energy.

Appearance and texture are of a nice, soft straw color. Also, it is an excellent sound insulator. It is frequently rendered, yet it looks fantastic when left unrendered.

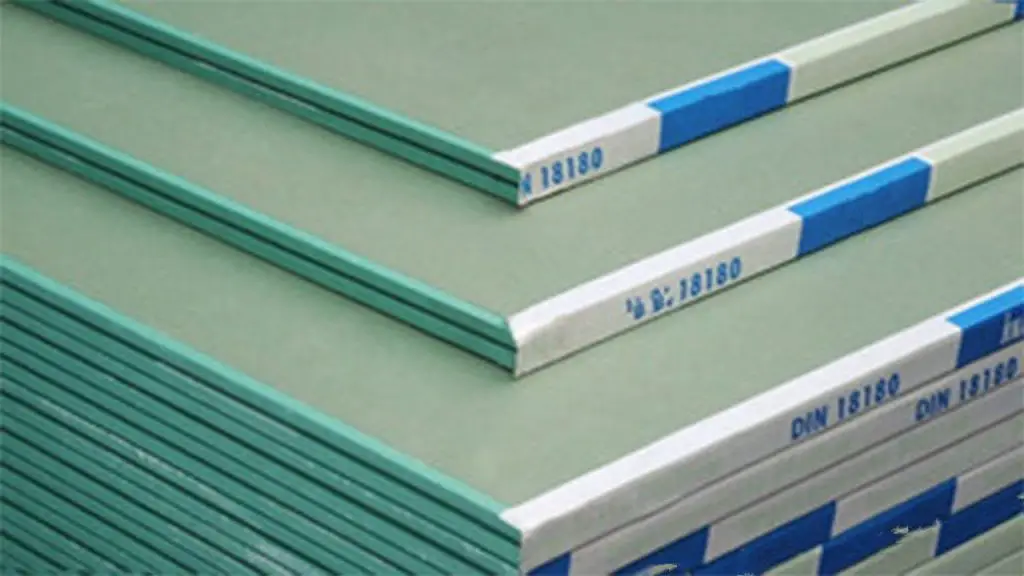

Gypsum Fiber

In stark contrast to plasterboard, gypsum-fiber is composed of cellulose fiber (recycled paper) and reinforced gypsum that acts as a structural component.

Whoever submitted the question is aware of the distinction between plasterboard and gypsum fiber, as well as why green building institutes consider it the optimal material for home walls.

You sense the change as soon as you enter the yard, holding plates. This is the primary reason for the superior thermal and acoustic insulation performance of gypsum-fiber panels over similar plasterboard panels of the same thickness.

When cutting the panels to install them, one is reminded of how good the material is. The installation process is almost the same, but gypsum-fiber panels are much harder to cut than plasterboard.

Gypsum-fiber stucco work is an important part of the installation process, and this is where the main difference between gypsum-fiber and plasterboard installation lies.

The gypsum-fiber panels must be left slightly apart from one another so that the seams may be filled with a particular grout that is likewise strengthened with cellulose fibers, therefore consolidating the panels into a single body.

Compacted earth

Rammed-earth walls are less common but very stunning. Rammed earth is made by pressing gravel, sand, silt, and a small amount of clay together between flat panels. It is a very ancient technique of wall construction that may be utilized as a structural wall.

Because it is produced from natural materials, it gives a home a lovely earthiness. Most of the time, aggregates come from nearby or your own property. This gives them a look that matches the colors of the natural terrain around them.

Breathaboard

In the EMBARC research, switching from drywall to compressed strawboard reduced CO2 emissions from a typical home from 965 kilograms to 6,357 kilograms. Breathaboard would presumably get similar results.

Then there are all the things we dislike about drywall; Breathaboard, as its name indicates, eliminates the majority of these issues since it breathes.

“Breathaboard passively controls the humidity inside the area because of its ability to breathe and absorb moisture,” says the company, reducing airborne pollutants, the possibility of condensation and mold or mildew growth, and occupant health issues, including asthma.

Robinson informed Treehugger that it is alkaline, making it resistant to mold and germs. And, unlike drywall, it doesn’t release hydrogen sulfide gas when it gets wet.

Hydrogen sulfide is not only dangerous because it smells bad, but also because it is very corrosive and can catch fire. Because of this, about 10% of the drywall scraps that are lost due to cutting and trimming cannot be thrown in the trash and are considered hazardous waste.

Between 2.6 and 3.12 billion square feet of the material must be treated individually in the United States alone.

The fact that Breathaboard is 100% compostable and “absolutely biodegradable and non-toxic, and the trash or off-cuts can even be utilized as fertilizer” is a significant, underrated benefit.

Bricks

Bricks may provide thermal mass benefits to your home, which will stabilize the interior temperature by storing and releasing heat as needed.

There are a multitude of forms, colors, textures, and installation patterns from which to pick, so there are countless options to design something wholly distinctive and captivating.

Recycled bricks are popular in the design industry and among design fans. They may also be a very cost-effective solution. Plus, you will save bricks from being thrown away needlessly, so it’s a win-win situation.

If you already have bricks in your home that you don’t like, rather than removing them, consider painting or whitewashing them to lighten the space.

From a sustainability standpoint, it is always preferable to keep what you have instead of purchasing anything new.

Conclusion

Plasterboard and fiber cement have been pillars of the building and construction industry for more than a century, used for everything from ceilings and floors to cladding and decking.

And while it is evident that these items are versatile and easy to use, changing expectations in the construction and design professions as well as the larger community have raised the demand for alternative alternatives.

The largest problem confronting the industry today is lowering the carbon footprint of the built environment, as well as the expectation that every aspect of construction, from material production to continuing performance, will prioritize eco-friendly building.

While putting an emphasis on eco-friendly construction, it is vital that performance is not compromised and that strength, safety, and longevity remain essential qualities.